Backflushing a plate heat exchanger (PHE) is a critical maintenance process that helps maintain its efficiency, extend its lifespan, and ensure optimal thermal performance. In industries where PHEs are used to transfer heat between fluids, debris, scale, and other residues can accumulate over time, reducing heat transfer efficiency and increasing energy costs. This article explores the backflushing process, its benefits, and best practices to keep your plate heat exchanger running smoothly and efficiently, minimizing downtime and maximizing performance.

Why to clean your heat exchanger with backflushing:

- Prevent biological growth on the plate

- Remove debris, sediment and mud

- Prolong service intervals

- Reduce shutdowns

- Increase gasket lifetime, less opening and closing

- Less risk of damaging plates and crushing gaskets when frequent opening and closing

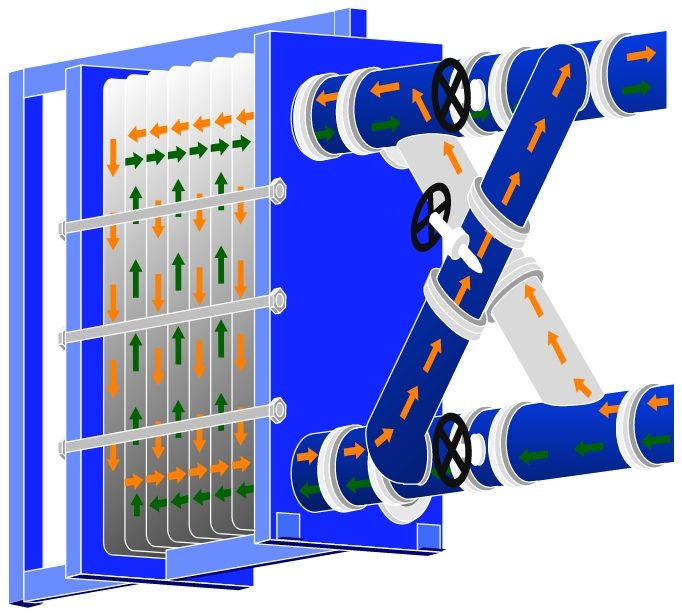

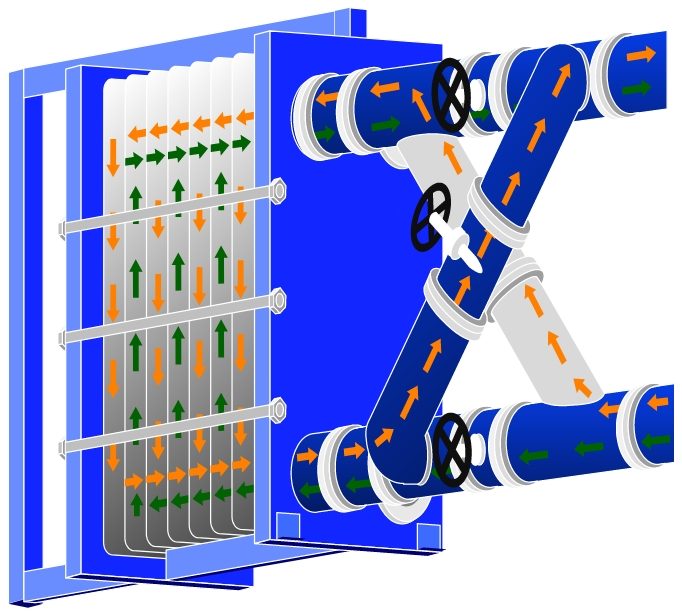

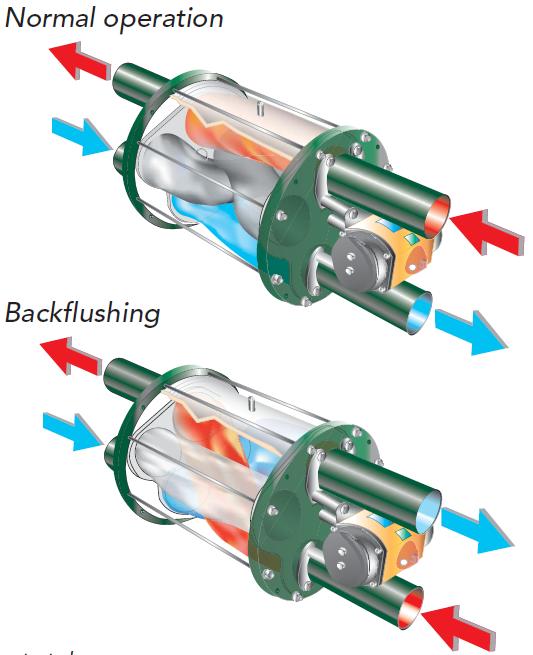

Backflushing means reversal of the flow in the heat exchanger for a short period of time thereby flushing out accumulated debris from the heat exchanger inlet channel.

What are advantages of heat exchanger backflush capability?

- Convenient self cleaning ability

- Longer service intervals

- Increased gasket lifetime.

Is there a risk of water hammering?

Answer is no.

How often should one backflush heat exchanger?

It depends on the installation, however as a rule of thumb

Backflush for 1/2 to 1 minute – for Parallel flow for a short time

there is reduced heat transfer during flushing, however this is less than 1-3% loss if flushed once an hour.

Frequency of backflushing heat exchanger for various fouling risks

- Biological fouling: Every 30 minutes

- Mud: Every 60 – 120 minutes

- Debris, sand: 2 – 4 times every 24hours

- Sea-shells, mussels: Twice every 24hours

Types of heat exchanger backflushing Mechanisms

| Cross over Piping arrangement | 4-way valve | Cylinder Valve |

|  |  |

|  | |