Keeping plate and frame heat exchangers (PHEs) in optimal working condition is critical for efficient heat transfer in a variety of industrial applications, from HVAC systems to power generation and chemical processing. Over time, however, heat exchangers can accumulate deposits like scaling, fouling, and corrosion, which significantly reduce their performance and cause possible damage to auxiliary downstream equipment. Our professional cleaning and refurbishment service is designed to restore dirty, clogged, damaged or inefficient heat exchangers back to peak operating condition, extending their lifespan and improving energy efficiency.

Why Regular Heat Exchanger Maintenance is Essential

When plate and frame heat exchangers are neglected, deposits build up on the plates, restricting heat transfer and decreasing efficiency. This results in higher energy consumption and increased operational costs. Additionally, corrosion and scaling can lead to equipment breakdown, risking expensive repairs or replacements.

A Clean in Place (CIP) system cannot be used to effectively clean a clogged plate and frame heat exchanger. CIP systems are designed to circulate cleaning solutions through equipment in a way that removes residue and minor fouling without disassembling the components. However, in the case of a plate and frame heat exchanger that has become clogged, the blockage prevents adequate flow of the cleaning solution, which limits its effectiveness. To properly clean a clogged heat exchanger, it typically needs to be disassembled to manually remove the buildup and ensure that all passages are thoroughly cleared, allowing for restored flow and optimal performance.

Our service focuses on proactive maintenance and thorough cleaning to:

- Restore thermal efficiency: Removing fouling and deposits to enhance heat transfer.

- Reduce energy costs: Restoring peak efficiency for lower energy consumption.

- Extend equipment life: Minimizing corrosion and wear, reducing the need for frequent replacements.

- Maintain regulatory compliance: Ensuring that your equipment meets health and safety standards for cleaner and more sustainable operations.

Our Plate and Frame Heat Exchanger Cleaning Process

Our cleaning process combines industry-leading techniques with top-grade equipment to ensure thorough refurbishment without damaging delicate components (read more here). Here’s an overview of our meticulous cleaning process:

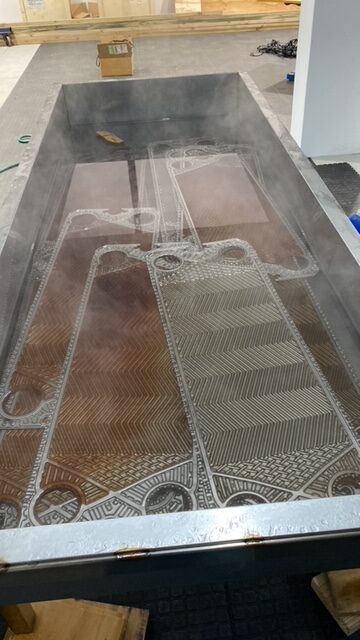

Inspection and Assessment: We begin with a detailed examination to identify fouling, corrosion, or any damage to the plates and gaskets. This helps us tailor the cleaning process to the specific condition of your heat exchanger.

Disassembly and Plate Cleaning: We carefully disassemble the unit and separate the plates, then remove all deposits using safe, eco-friendly cleaning agents that eliminate scaling, fouling, and corrosion. Our methods ensure a deep clean without compromising the integrity of the plates or gaskets.

Gasket Replacement and Reassembly: If necessary, we replace worn or damaged gaskets to prevent leaks and restore the seal quality of the unit. After reassembly, we conduct a final inspection to ensure everything is in perfect working order.

Pressure Testing: Following cleaning, we reassemble the plates and conduct a pressure test to identify any leaks or weak points. This step is essential to ensure that your heat exchanger is restored to its original level of performance and safety.

Why Choose Our Heat Exchanger Cleaning Service?

We offer industry expertise, technical precision, and a customer-centered approach. Our clients benefit from:

- Experienced Technicians: Our team has extensive experience handling plate and frame heat exchangers across industries, ensuring the highest quality of service.

- Advanced Cleaning Techniques: We use state-of-the-art cleaning methods and equipment tailored to your specific heat exchanger’s needs.

- Fast Turnaround Times: We understand that downtime can impact your business, so we work efficiently to minimize interruptions to your operations.

Contact Us for Your Heat Exchanger Cleaning Needs

Whether you’re experiencing a loss in efficiency, increased energy costs, or suspect fouling in your heat exchangers, our cleaning and refurbishment service can help. Contact us today to discuss your needs and let our team bring your plate and frame heat exchangers back to optimal working condition, helping you save on energy costs and extend the lifespan of your equipment.

By investing in regular heat exchanger maintenance, you’re not only ensuring consistent performance but also taking a step toward sustainable, efficient operations. Reach out today, and let’s get your heat exchangers working like new again!